Product List

- Spray Guns

- Pipe Reel

- Regulators

- High Pressure Cleaner

- Spray deodorization, disinfection, cooling, dust reduction system

- High-pressure hot and cold water cleaners

- Tank cleaning equipment

- Central cleaning system

- Multifunctional three-wheeled sanitation truck

- High pressure plunger pump series

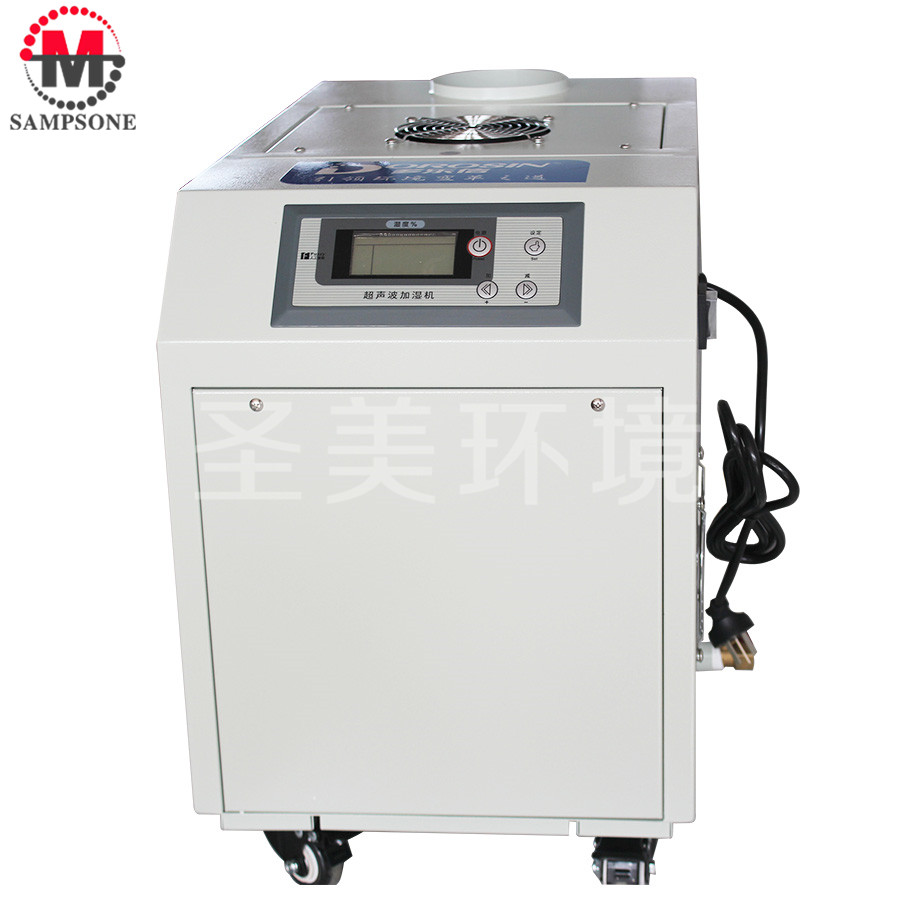

High-pressure spraying mainframe

Vehicle mounted hot and cold water pressure washer

Mobile hot and cold water pressure washer

Italian original imported cold and hot water cleaning machine

High pressure cleaning accessories

Wuxi Shengmei Environmental Technology Co., Ltd.

Add:No.595 Jinhui Road, Huishan Economic Development Zone, Wuxi City, Jiangsu, China

Tel:4000 680 799

Fax:+86 510-83623799

Contact:General Manager Zhou

Mob:+86 13093013656

Contact:Manager Zhou

Mob:+86 13395145350

E-mail:sampsone@126.com

| RW200.08 Tank cleaning equipment |

Cleaning principle

At present, high-pressure cleaner is widely used in metallurgy, mining, power plant, light industry, oil field, petrochemical industry, etc. High cleaning efficiency, good cleaning effect, water and energy saving, environmental protection and no pollution are its main features. In this article, we will mainly introduce the applicability of high-pressure cleaning machine in oil tank cleaning.

Traditional oil tank cleaning method is mainly steam fumigation cleaning, the principle is to steam pipe into the tank to be cleaned, and then the use of steam heat to the inner wall of the tank heating, so that the residual material attached to the inner wall of the tank volatilized and discharged from the tank, followed by the operator down to the tank inspection, and finally pass into the hot air drying, in order to achieve the purpose of cleaning oil tanks.

Steam heating usually takes four to eight hours, consumption is large, cleaning efficiency is very low. The residual materials volatile harmful substances directly into the atmosphere, the surrounding environment is more polluted, and it is difficult to deal with. Steam fumigation is strictly a manual cleaning method, requiring manual use of special brushes dipped in cleaning agent to scrub the inside of the tank, with a large labor intensity, and easy to produce harmful effects on the operator's body shortcomings. This cleaning method has obviously not adapted to environmental requirements.

High-pressure washing machine cleaning tank is through the three-dimensional tank washer sprayed out of the multi-angle all-round high-pressure water jets on the tank wall attached to the dirt and rust to combat, so as to remove the dirt, from beginning to end is fully automatic, while the vacuum pump will be pumped to the wastewater tank. After the flushing is completed by gas replacement, the operation workers go down to the tanker for inspection and then pass into the hot air for drying, and finally complete the cleaning of the inner wall of the tank thoroughly.

Technical parameters of tank cleaning system equipment

1、 The main control system equipment explosion-proof requirements design. Explosion-proof motor power 15KW, voltage 380V,50HZ.

2、 Corrosion-resistant Italian bronze nickel-plated high-pressure pump: working pressure 150 kg, flow rate 50 liters / min.

3、 High pressure water pipeline: 400kg high pressure hose.

4、 Explosion-proof motor-driven high-pressure three-dimensional cleaning nozzle.

5、 Stainless steel automatic telescopic mechanism

6、 Safe and non-polluting filtering water connection tank

Applicability of tank cleaning equipment:

1, High cleaning efficiency, can be a full 360 degree coverage of the tank jet cleaning.

2, Cleaning time is short, the general single tank all cleaning operations only need to be within an hour.

3, A high degree of automation, the operator's labor intensity is very low, saving manpower and material resources.

4, More safe and reliable, the cleaning pressure can be adjusted, the appropriate pressure will not cause damage to the inner wall of the tank; and significantly reduce the time of the operator into the tank, to ensure safe operation.

Scope of adaptation

Mostly used in petrochemical, dairy products processing, storage tank storage, tank transportation and other tank equipment that needs cleaning.

Use and maintenance

1. This machine is not suitable for use in a closed indoor environment again.

2. The power source of water must be cut off after each work.

3. Never use the machine when the cable or some important parts such as safety device, high pressure pipe, gun, etc. are damaged.

4. Only use liquid detergent within the design range or recommended by the manufacturer, not strong acidic or strong alkaline detergent with high concentration. Use caution whenever using cleaners.

5. Do not start the machine when there are people staying at the work site, unless the non-other mother is wearing protective clothing.

6. High-pressure spraying can be dangerous if not done correctly. Never point the gun at other people, animals, electrical devices or the machine.

7. High pressure hose, accessories and connections are very important for the safe use of the machine, it is recommended to use the manufacturer's recommended accessories. (Proper use, prevent its twisting, falling and crashing, and protect these accessories from damage is important to the machine)

8. Never use the gun to point at yourself to clean clothes and shoes.

9. Never allow children or people unfamiliar with the machine to operate and use.

10. Safety devices include: gun safety buckle, electrical overload protection device, high-pressure pump relief protection valve.

11. For the machine without automatic stop function, must not be operated for more than 2 minutes with the gun off, otherwise, the temperature of the circulating water will be hormonally elevated and damage the seal pump.

12. For the machine with automatic stop function, the automatic stop time should not exceed 5 minutes.

13. After each operation is completed, you need to press the shutdown switch OFF.

14. It is normal for the new machine to have a few drops of water dripping out from the water seal when it is operated under normal conditions of experiment again.

15. Please do not work in a sealed or inadequately ventilated environment, and never cover the machine.

16. Never use the machine again in the case of thunder or rain, do not spray water on the machine or electrically charged body.

17. When using any machine, especially observe the following rules.

18. Never touch the machine when your hands are wet or barefoot.

19. When the machine is starting, never pull the plug out of the socket at will.

20. When the machine in the operation of the current suddenly interrupted, please immediately shut down the machine.

21. It is strictly forbidden to use the machine in a flammable and explosive environment.

Automatic stop system (optional)

Please note that this session is equipped with ASS (Automatic Stop System) controlled by the pressure valve, in the case of power on, press or release the trigger on the gun, the machine will automatically start or stop, each time after releasing the trigger to open the safety buckle on the gun, to prevent the gun shell accidentally open, resulting in a dangerous accidental start of the machine.

1. Any accidental start-up without pressing the gun is caused by the presence of air bubbles or malfunctions in the water.

2. In the case of automatic stop system working mode, personnel should not leave the machine for more than 5 minutes, otherwise, for safety reasons, the current must be turned off.

3. Please check if the standard devices such as gun and high pressure hose are connected correctly and if there are any water leaks.

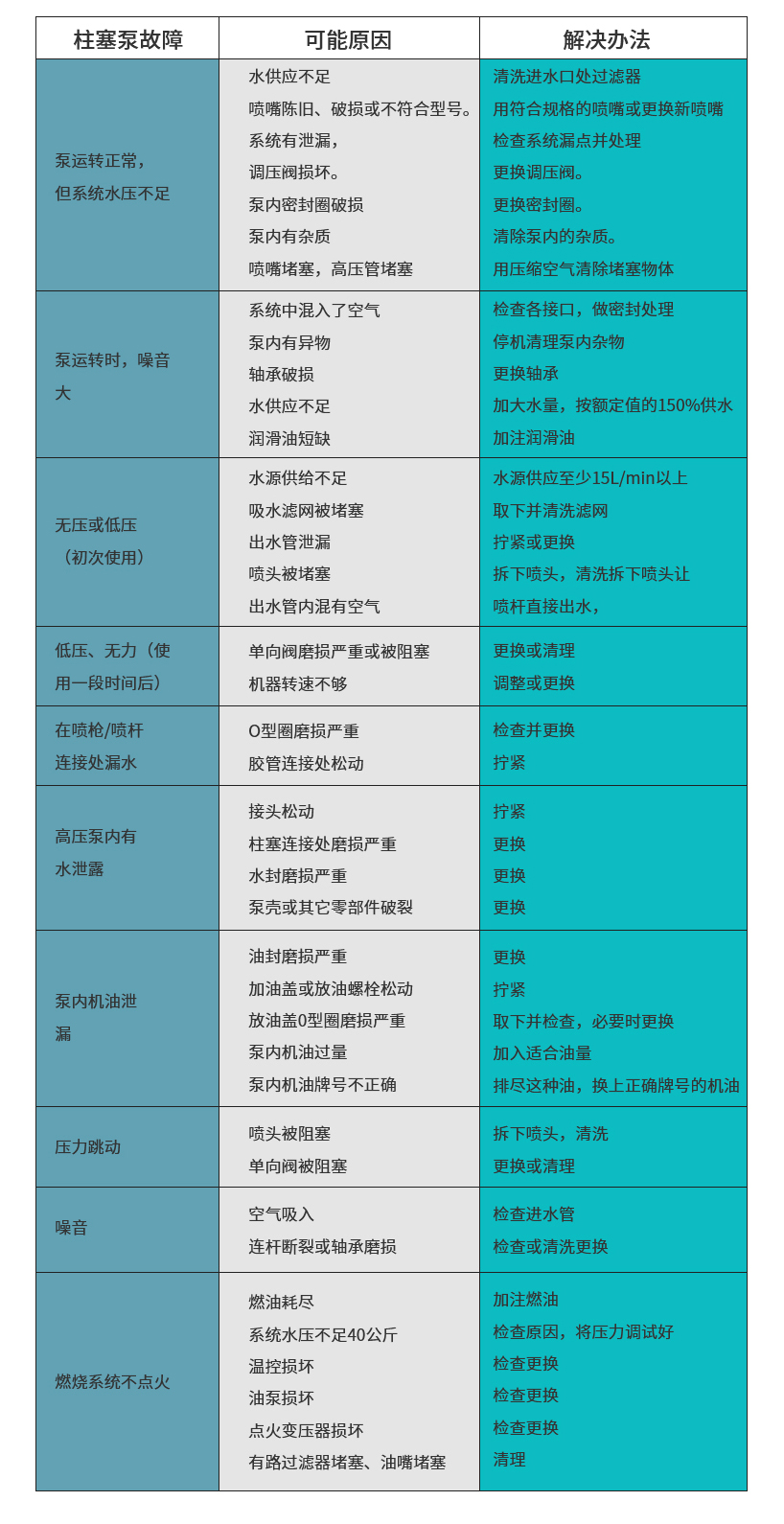

Common faults and troubleshooting

After-sales guarantee

|

|

|

| Tank cleaning equipment |

Tank cleaning equipment |

Previous: A42R-360° tank cleaning equipment Next: 暂无

Related News

- 2023-05-08 Tank cleaning systems in practice

- 2023-05-08 How to clean the closed polymerization reactor?

- 2023-05-08 Reactor cleaning high-pressure cleaning workflow

- 2023-05-08 What are the requirements to be met by the reactor...

- 2023-05-08 Key measurements for tank cleaning

- 2023-05-08 High-pressure cleaners in special areas of applica...

![[field:companyurl]](/EN/template/1/images/footer_logo.png)