Product List

- Spray Guns

- Pipe Reel

- Regulators

- High Pressure Cleaner

- Spray deodorization, disinfection, cooling, dust reduction system

- High-pressure hot and cold water cleaners

- Tank cleaning equipment

- Central cleaning system

- Multifunctional three-wheeled sanitation truck

- High pressure plunger pump series

High-pressure spraying mainframe

Vehicle mounted hot and cold water pressure washer

Mobile hot and cold water pressure washer

Italian original imported cold and hot water cleaning machine

High pressure cleaning accessories

Wuxi Shengmei Environmental Technology Co., Ltd.

Add:No.595 Jinhui Road, Huishan Economic Development Zone, Wuxi City, Jiangsu, China

Tel:4000 680 799

Fax:+86 510-83623799

Contact:General Manager Zhou

Mob:+86 13093013656

Contact:Manager Zhou

Mob:+86 13395145350

E-mail:sampsone@126.com

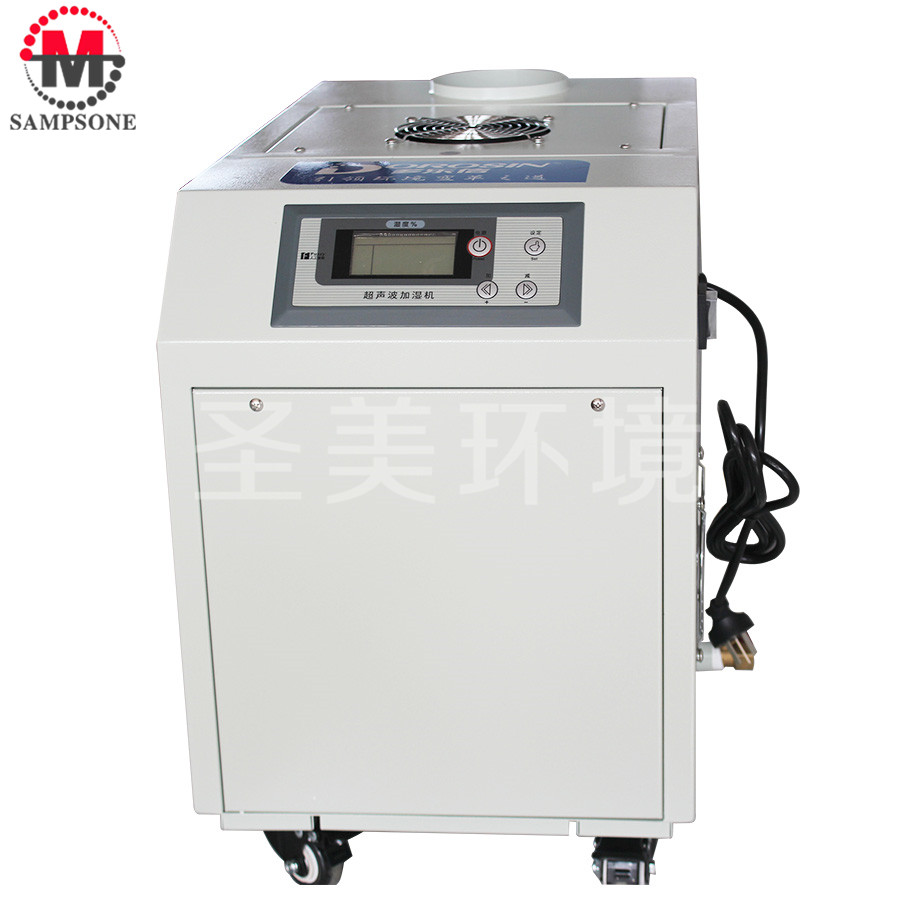

| SM-3070 High pressure spraying mainframe |

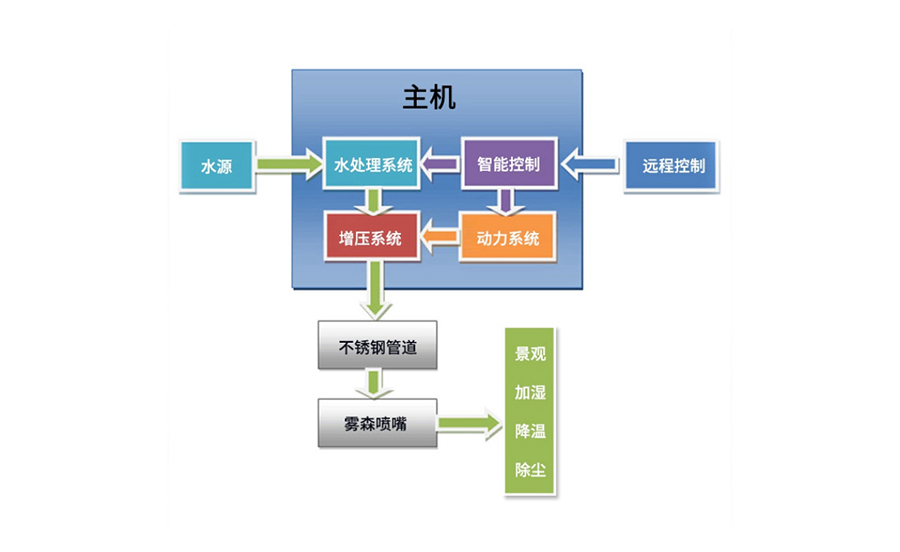

Working principle

The working principle of the latest generation of spray humidifier of Wuxi Shengmei is that the water is pressurized by the humidifier host and then sprayed by the special nozzle, the sprayed water mist and air for heat and humidity exchange so as to achieve the purpose of humidification of the air.

This humidification method belongs to the enthalpy humidification method, in the humidification at the same time can also play a certain cooling effect, it has the advantages of energy saving, safety, reliability, etc., has a very high cost performance ratio.

Specification parameters

|

Product Model |

SM-3070 Spray disinfection mainframe |

|

Working flow(L/min) |

30L |

|

Motor power(Kw) |

3KW-6P |

|

Work stress(MPa) |

0-7 |

|

Power supply |

380V/50Hz |

| Size(mm) | 900*625*1310 |

| Domestic pumps | SM4020 |

Performance features

* Integrated operation: Integrated system processing, increased reliability, improved operational stability, safety, and ease of maintenance.

* Spraying reliable: the use of imported transparent water filter, fully solve the impact of water quality problems.

* Simple operation: The main machine is equipped with temperature and humidity automatic inspection system, temperature and humidity adjustment are automatically completed by the system, safe and reliable operation, truly realize unmanned management. Directly powered by water pressure, no air compressor and other auxiliary equipment.

——Good atomization effect, particle diameter is only 3-5 microns.

——When you stop humidification, the system automatically drains the remaining water in the pipeline to prevent scaling.

——Simple installation, easy operation, minimal maintenance work, and unmanned system operation.

——The precision-machined back-splash type micro-mist nozzle has good abrasion resistance and no dripping.

——The system is equipped with a water cut-off protection system for stable and reliable operation.

Applicable fields

-

Industry: textile factory, cigarette factory, electronic plant, printing plant, automobile painting plant, wood (furniture) processing plant, fire (explosives) production plant and other humidification; power plant plant, steel plant plant cooling; brewing, food industry, high temperature and high humidity environmental conditions of humidification and cooling or disinfection.

Agriculture: cold storage, greenhouse sheds, livestock breeding, flower nurseries, edible fungus cultivation and other humidification, cooling spraying, fertilization, etc.

Landscape creation: the ultra-fine fog particles suspended in the air like clouds moving with the wind, sometimes hidden, creating a fascinating landscape effect; at the same time, the ultra-fine fog particles contain a large number of negative ions, increasing the oxygen content of the air, greatly creating and improving the environment for people to live and live. -

Product use and maintenance

1、After opening the box, check the packing list one by one, attach the spare parts and documents to be kept properly.

2、Inject L-AN46~68 (old brand 30#~40#) mechanical oil into the pump to 1/2 position.

3、Check whether the nuts and screws at each linkage are loose.

4、Move the machine to the workplace and check carefully whether the power supply meets the requirements.

5、The machine working pressure 5-6Mpa is appropriate, if there are special requirements, the machine can also be raised to 7Mpa, but as far as possible to reduce the machine in the high pressure state of long-term operation, the pressure adjustment in the injection state.

6、After 50 hours of use, the oil must be replaced in the new machine. When the oil is released, the bottom screw is removed to release the oil in the pump, followed by the injection of new oil, which is very important to extend the service life of the machine. In the cumulative use to 300 hours and then replace the oil with the same method, after every 300-500 hours to replace the oil.

7, long-term use or low winter temperatures, the host high-pressure pump should be drained of water, the method is to close the water inlet valve, while disconnecting the host outlet, turn on the dehydration run for about half a minute. Then loosen the end of a nozzle to drain the water left in the high-pressure pipe to prevent the pipeline from freezing.

Common faults and troubleshooting

|

Failure |

Reason |

Exclusion method |

|

The machine does not start working and stops automatically when running |

1. No power supply or poor socket contact. 2. Damaged switch or contactor. 3. Insufficient water pressure for water supply. |

1. Check the power supply, plug it in. 2. Have an electrician check the grid lines. 3. Check the water supply, clean the filter or replace it. |

|

Nozzle does not produce water or water pressure is unstable |

1. Clogged spray hole. 2. Air in the pipeline. 3. Rupture of the water high-pressure pipe. 4. Clogged water inlet filter. |

1. Remove the nozzle to clean. 2. Start the machine to loosen a nozzle to discharge the air. 3. Replace the water pipe. 4. Clean the filter or replace |

|

Water leakage at joints |

The screw at the threaded connection is not tightened |

Tighten the screws |

|

Crankcase heating |

1. Too much oil. 2. Too little oil and cause the connecting rod to bite the shaft |

1. Drain the excess oil, oil level to the oil mark 1/2. 2. Warranty |

|

Pressure can not be adjusted up |

1. The nozzle aperture is too large. 2. The water supply line is leaking. 3. The high pressure line is leaking. |

1. Replace the nozzle. 2. Check the water supply. 3. Check the outlet pipe. |

|

No water discharge or too small drainage |

1. Clogged spray hole. 2. Air leakage in water supply line. 3. Clogged water inlet filter. |

1. Remove the nozzle to clean or replace. 2. Check the water supply. 3. Clean the water inlet filter or replace. |

|

Temperature and humidity controller malfunction |

1. Check whether the detector head is covered by debris. 2. Check whether the detector head connection line is off. 3. The controller is damaged |

1. Clear the debris. 2. Reconnect the wiring. 3. Replace the controller |

This equipment if there are other failures please contact us: 13196538895

Notes:

1, inverter settings see the random inverter manual, note: the relevant parameters of the inverter has been set before the factory, non-professionals please do not adjust.

2、The time control switch and time relay can be adjusted and set by the customer according to the actual equipment use, see the manual of the random time control switch and time relay for the setting method.

After-sales guarantee

Safety rules

1、The machine must be checked before use to supply power, while according to the safety of electricity regulations, the power must be installed leakage protection switch.

2、The machine must be safely grounded when in use, be sure to use a good grounded socket with it, and must cut off the power when not in use.

3、Prevent the power cord from touching the heat source, oil, sharp knife edge, etc. Do not place the power cord at the intersection, so as not to damage the wire and dangerous.

4, the user must cut off the power supply before maintenance and repair.

5, such as motor, electrical failure, the user must ask professional maintenance personnel to repair, in order to avoid danger.

6、It is strictly prohibited to be operated by children and untrained people.

7, the pump is not fueled, idling is strictly prohibited.

8、The machine uses room temperature water, the water temperature should not exceed 45℃. In 45℃ or lower environment, pay attention to freeze protection.

9、When the power supply line or important parts of the equipment are damaged, it is prohibited to use the equipment.

10、Usually, the working pressure has been adjusted at the factory, so please do not adjust it by yourself.

11、In order to ensure the safe use of the equipment, should use the original parts provided by our factory or approved.

12、The nozzle must use the matching nozzle provided by our factory.

13, the user must use the machine according to the above "rules", if you violate the above "rules" requirements, then all the consequences are their own responsibility.

|

|

|

|

Spray deodorization, disinfection, cooling, dust reduction system |

Spray deodorization, disinfection, cooling, dust reduction system |

Previous: SM-2080 High pressure washer Next: RC-M Italy AR piston pump

Related News

- 2023-05-08 Tank cleaning systems in practice

- 2023-05-08 How to clean the closed polymerization reactor?

- 2023-05-08 Reactor cleaning high-pressure cleaning workflow

- 2023-05-08 What are the requirements to be met by the reactor...

- 2023-05-08 Key measurements for tank cleaning

- 2023-05-08 High-pressure cleaners in special areas of applica...

![[field:companyurl]](/EN/template/1/images/footer_logo.png)