Product List

- Spray Guns

- Pipe Reel

- Regulators

- High Pressure Cleaner

- Spray deodorization, disinfection, cooling, dust reduction system

- High-pressure hot and cold water cleaners

- Tank cleaning equipment

- Central cleaning system

- Multifunctional three-wheeled sanitation truck

- High pressure plunger pump series

High-pressure spraying mainframe

Vehicle mounted hot and cold water pressure washer

Mobile hot and cold water pressure washer

Italian original imported cold and hot water cleaning machine

High pressure cleaning accessories

Wuxi Shengmei Environmental Technology Co., Ltd.

Add:No.595 Jinhui Road, Huishan Economic Development Zone, Wuxi City, Jiangsu, China

Tel:4000 680 799

Fax:+86 510-83623799

Contact:General Manager Zhou

Mob:+86 13093013656

Contact:Manager Zhou

Mob:+86 13395145350

E-mail:sampsone@126.com

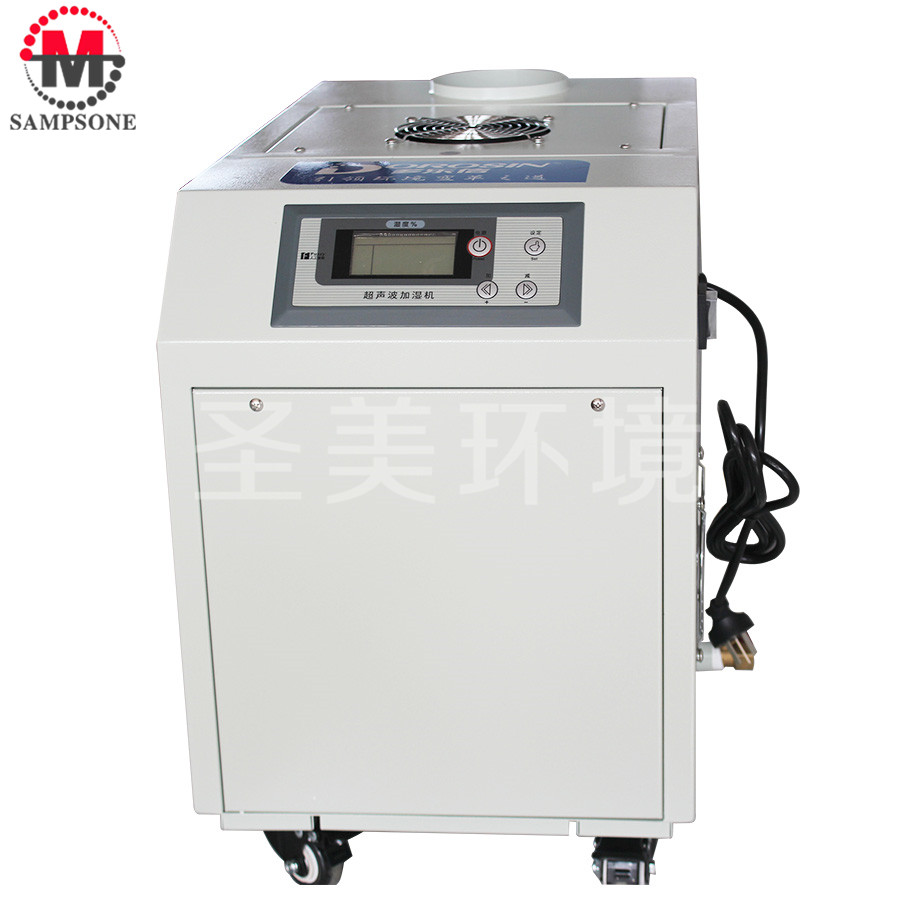

| DC3016 Vehicle Mounted High Pressure Washer |

一、Working principle

Wuxi Shengmei high pressure washer uses a set of valves and pump head to form a system where the plunger pulls water into the inlet valve and pressurizes it to pass through the outlet valve. The valve controls the water through the pump by preventing backflow. The valve consists of a spring and a bracket, and the pressure operation is accomplished due to the different pressure difference between the two sides of the valve. When the pressure acting on the valve is greater than the capacity of the spring, the valve opens. In the opposite stroke, the water automatically squeezes the holder against the valve seat, keeping the valve closed and preventing backflow.

The heart of the high-pressure cleaner is the high-pressure pump, and they are in an irreplaceable position. The total stroke L of the plunger reciprocating motion of the plunger pump is constant and is determined by the lift of the cam. The size of the oil supply per cycle of the plunger depends on the oil supply stroke, which is not controlled by the camshaft and is variable. The start of the oil supply does not vary with the oil supply stroke. Turning the plunger can change the end time of oil supply and thus the amount of oil supply. When the plunger pump works, the cam on the camshaft of the injection pump and the plunger spring force the plunger to make upward and downward reciprocating movements, thus completing the task of pumping oil.

When the plunger moves in one direction, there is negative pressure in the cylinder, then one check valve is opened and the liquid is sucked into the cylinder, when the plunger moves in the other direction, the liquid is compressed and the other check valve is opened and the liquid sucked into the cylinder is discharged. This way of working after continuous movement formed a continuous oil supply.

Product parameters

|

Product model |

SM-DC-72-7.5 |

|

Working flow(L/min) |

15L |

|

Motor power(Kw) |

7.5 |

|

Work stress(Bar) |

250 |

|

Rated voltage |

72V |

| Motor | DC brushless permanent magnet motor |

| Rated speed | 1495 |

| Italy AR pump | RG24.10C |

Adaptation scenarios

Product use and maintenance

1. This machine is not suitable for use in a closed indoor environment again.

2. The power source of water must be cut off after each work.

3. Never use the machine when the cable or some important parts such as safety device, high pressure pipe, gun, etc. are damaged.

4. Only use liquid detergent within the design range or recommended by the manufacturer, not strong acidic or strong alkaline detergent with high concentration. Use caution whenever using cleaners.

5. Do not start the machine when there are people staying at the work site, unless the non-other mother is wearing protective clothing.

6. High-pressure spraying can be dangerous if not done correctly. Never point the gun at other people, animals, electrical devices or the machine.

7. High pressure hose, accessories and connections are very important for the safe use of the machine, it is recommended to use the manufacturer's recommended accessories. (Proper use, prevent its twisting, falling and crashing, and protect these accessories from damage is important to the machine)

8. Never use the gun to point at yourself to clean clothes and shoes.

9. Never allow children or people unfamiliar with the machine to operate and use.

10. Safety devices include: gun safety buckle, electrical overload protection device, high-pressure pump relief protection valve.

11. For the machine without automatic stop function, must not be operated for more than 2 minutes with the gun off, otherwise, the temperature of the circulating water will be hormonally elevated and damage the seal pump.

12. For the machine with automatic stop function, the automatic stop time should not exceed 5 minutes.

13. After each operation is completed, you need to press the shutdown switch OFF.

14. It is normal for the new machine to have a few drops of water dripping out from the water seal when it is operated under normal conditions of experiment again.

15. Please do not work in a sealed or inadequately ventilated environment, and never cover the machine.

16. Never use the machine again in the case of thunder or rain, do not spray water on the machine or electrically charged body.

17. When using any machine, especially observe the following rules.

18. Never touch the machine when your hands are wet or barefoot.

19. When the machine is starting, never pull the plug out of the socket at will.

20. When the machine in the operation of the current suddenly interrupted, please immediately shut down the machine.

21. It is strictly forbidden to use the machine in a flammable and explosive environment.

Automatic stop system (optional)

Please note that this session is equipped with ASS (Automatic Stop System) controlled by the pressure valve, in the case of power on, press or release the trigger on the gun, the machine will automatically start or stop, each time after releasing the trigger to open the safety buckle on the gun, to prevent the gun shell accidentally open, resulting in a dangerous accidental start of the machine.

1. Any accidental start-up without pressing the gun is caused by the presence of air bubbles or malfunctions in the water.

2. In the case of automatic stop system working mode, personnel should not leave the machine for more than 5 minutes, otherwise, for safety reasons, the current must be turned off.

3. Please check if the standard devices such as gun and high pressure hose are connected correctly and if there are any water leaks.

After-sales service and guarantee

High pressure hot and cold water machine

Previous: SM-DC-72-7.5 Vehicle Mounted High Pressure Washer Next: SMGX250/15H1 High temperature high pressure cleaner

Related News

- 2023-05-08 Tank cleaning systems in practice

- 2023-05-08 How to clean the closed polymerization reactor?

- 2023-05-08 Reactor cleaning high-pressure cleaning workflow

- 2023-05-08 What are the requirements to be met by the reactor...

- 2023-05-08 Key measurements for tank cleaning

- 2023-05-08 High-pressure cleaners in special areas of applica...

![[field:companyurl]](/EN/template/1/images/footer_logo.png)